At horizont, we attach great importance to making both our processes and our products sustainable. In the past, several projects have already been implemented that contribute to environmental protection and are presented on this page. In the future, too, horizont will actively promote sustainability in the company and continuously optimise processes and products in this context.

Our green line

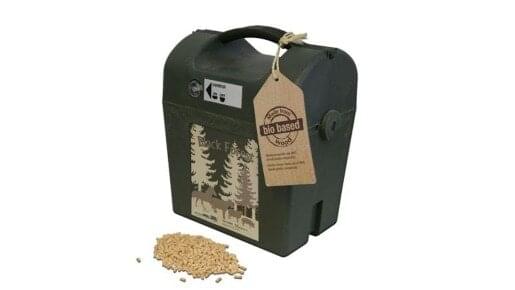

With the climate-neutral plastic based on renewable raw materials, we succeed in bringing the world's first bio-based pasture fence housing onto the market. With the new Greenline, we focus on a future-oriented and environmentally friendly product range.

Combined heat and power plant

We use combined heat and power generation to supply our buildings with energy. Our combined heat and power plant produces up to 150,000 KWh of electricity per year in addition to the required heat. High-efficiency pumps also distribute the heat optimally in the building.

Photovoltaic system

Through the use of a photovoltaic system on an area of about 4500m², we generate a maximum of 700 KWP, about 50% of our total electricity purchases ourselves. By consciously changing the energy supply contracts, the difference is obtained through green electricity.

Lead-free components & own recycling

In accordance with the European Directive, horizont uses only RoHS-compliant (lead-free) components, factory and auxiliary materials in purchasing and production. We have also been using lead-free solder for soldering the circuit boards since 2005. horizont electric fencing equipment is made of various plastics, which are generally coloured with lead-free and cadmium-free paints. Housing parts of our devices are marked with a material label, so that in case of disposal the plastic parts can be separated according to type. Our own plastic "waste" is ground and reused for injection moulding in-house without any significant loss of quality.

Disposal & recycling of electrical appliances

The symbol of the "crossed-out dustbin" on an item or on the packaging indicates that it cannot be disposed of in the normal household waste. The item must be taken to an appropriate collection point for the return and reuse of old electrical and electronic equipment. Batteries and accumulators must be removed beforehand and disposed of separately. For more detailed information on the disposal of the appliance, contact your local authority, the waste recycling service in your region or the specialist dealer from whom you purchased this appliance.

Battery recycling & disposal

Battery recycling means the material recycling of batteries. According to the European Directive 2006/66/EC (BATTERY), consumers are obliged to return used batteries and retailers, public waste management authorities, manufacturers and importers are obliged to take them back. Dry cell batteries for electric fence equipment supplied by horizont are free of lead and cadmium and can be used for recycling: zinc-carbon, zinc-air and alkaline-manganese batteries contain significant amounts of zinc, which is the main focus in the recycling of these batteries.

Use of renewable resources

horizont is continuously researching new ways to make production processes, manufacturing materials and thus also products more sustainable. For several years now, the company has been working on ways to use wood-based materials in combination with plastics. In a joint project with the University of Kassel, horizont is also developing a special, particularly impact-resistant and bio-based plastic by adding natural fibres (cellulose regenerated fibres).

Heat recovery of the compressor unit

One of the most important forms of energy for our production site is compressed air. Also here, a main focus was placed on the highest possible efficiency. By using a modern heat recovery system, it was possible to significantly increase the efficiency here.

LED technology

At our main location in Korbach, the entire lighting system was replaced by modern LED lighting. This has already demonstrably reduced energy costs by 40%.